INDICO

The INNO+ INDICO indirect air-cooling system is a standardised multi-component dry air-cooling system, consisting of a chiller, a thermal carrier (water-glycol) and heat exchangers. The system is designed to deliver conditioned inlet air to achieve optimal house temperature in hot and/or humid ambient climate.

An optimized house climate protects the animals from heat stress, improves feed conversion and lowers mortality during hot and humid periods. The system is applicable to closed housing for any kind of livestock (Cows, Poultry, Pigs and even Insects).

The INDICO system consists of the following key components:

- Chiller(s)

- Filters (skid)

- Buffer tank

- Pumps (skid)

- Valves (skid)

- Heat exchangers

- Piping

- Sensors

- Cabling

- Remote accessible visual control & monitoring

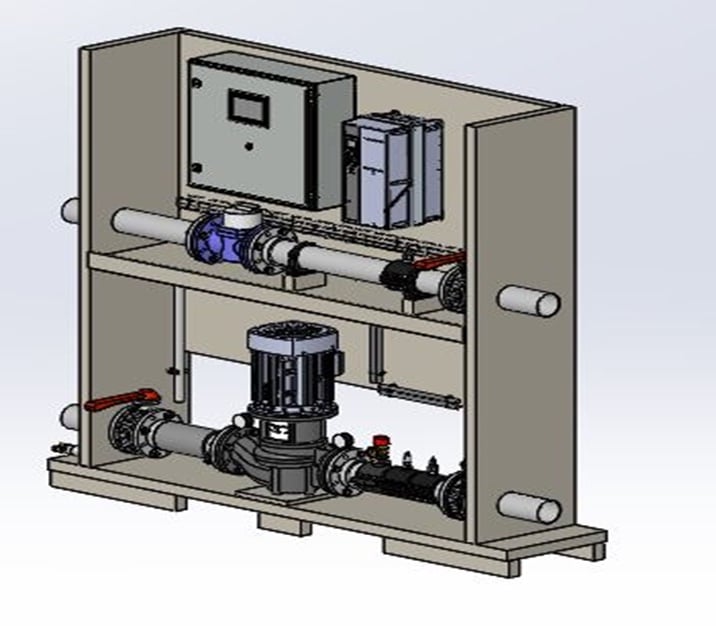

Pumps, valves and filters are preassembled onto standardized skids. These skids are delivered to the site as a single unit. The whole system is easy to install, can be assembled on-site and integrated into the house, where the skids and buffer tank are to be placed in an indoor technical room.

The INDICO system is available in cooling capacities ranging from 75kWth up to 3.2MWth. Larger can be handled by multiple individual systems in parallel. It is scalable up to five individually controlled sections by means of motorized valves on an extension skid. A combination with the Triple EEE heat recovery system for preconditioning air during wintertime is also available.

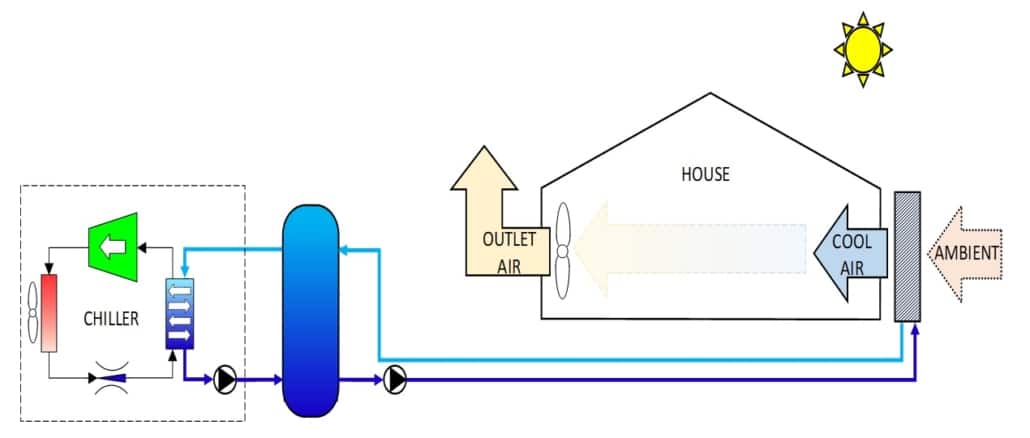

Working principle of the cooling system

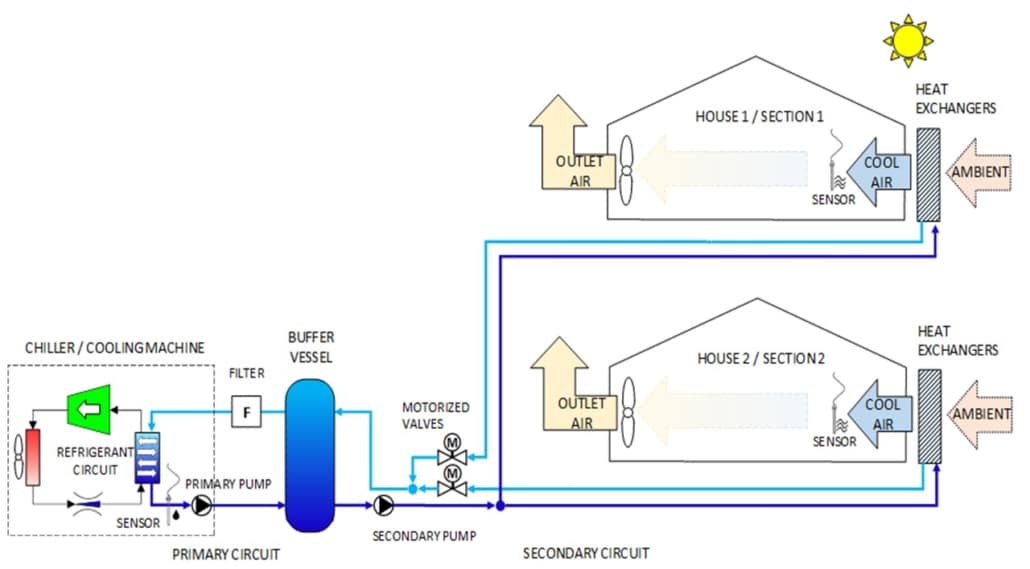

The schematic below shows the basic working principle and main components of the INDICO system for cooling two houses/sections:

- A coolant (water or preferably a water-glycol mixture) circulates in a primary circuit between a cooling machine and the buffer tank by means of a pump (could be either external or integrated in the cooling machine).

- A filter is integrated in the primary circuit – in the supply to the cooling machine – to protect the cooling machine from large particles that could block the coolant flow.

- The chiller cools by means of a refrigerant vapour-liquid compression/expansion cycle – the coolant to a preferred temperature of 9 degrees Celsius.

- The cooling machine via an integrated temperature sensor in the primary circuit controls the exiting coolant temperature.

- A secondary pump on the ‘pump skid’ circulates the coolant between the buffer vessel and the inlet heat exchangers of the different houses/sections.

- The inlet air temperature of each house is controlled by a system controller, to preferably 17 degrees Celsius – by means of coolant flow control and a temperature sensor in the inlet air.

- Coolant flow is controlled per house/section by means of the speed of the secondary pump on the ‘pump skid’ and by means of the motorized valves in the return line on the ‘valve skid’.

- The inlet air passes through the inlet heat exchanger and cools from ambient temperature to the preferred target of 17 degrees Celsius. Depending on ambient air condition, water vapour condenses from the air and forms condensate in the heat exchanger. Depending on the climate/humidity, the amount of condensate can be substantial.

- The system is controlled with sensors to monitor coolant flow and supply and return temperatures per house/section and with energy monitoring for the pumps and cooling machine.

- Data collected by sensors is used to calculate system efficiency, monitor annual power consumption, and evaluate nominal system operation.

- Collected data from sensors is stored locally in the controller (SD card) and is accessible and downloadable through the IXON online portal of Inno+ (when an internet connection is available on site).

Power consumption, Performance and Efficiency

Cooling power and energy consumption of INDICO varies extensively during the summer season and depends largely on the local outdoor climate and desired house conditions. The system operates as soon as the ambient air temperature exceeds 17 degrees Celsius.

Based on the integration of standard industrial cooling machines in the INDICO system, the whole system will run at an annual EER of 2.8 for extremely hot/humid to 3.4 for more moderate climate. This means that every consumed kW of electricity by the system converges into 2.8 to 3.4kW of cooling.

More information about the INDICO system, or a site and customer specific system calculation and offer?

Fill out the form below or connect to your local sales contact.

Interested? Get in touch with us!

Study proves it: air scrubber is a resource for energy

The Inno+ Triple EEE heat recovery system has been thoroughly studied over a long period of time by the University of Bonn. This research is part of their large-scale scientific study EnergARA. This research focuses on the potential of air scrubbers as energy sources.

In this study, two adjacent pig farms, each equipped with the Triple EEE system, have been compared. The second farm had an additional feature, namely Inno+’s Indico cooling system.

The result: Triple EEE turns the air scrubber into a powerful energy source, which provides significant energy savings and healthier animals.