InnoClean air scrubbers: for sustainable emission reduction

Innovative solutions for emission reduction in livestock farming and sustainable business operations

InnoClean offers advanced technologies for emission reduction, specifically designed to minimise the impact of livestock farms, insect farming facilities, and manure processing plants on the environment and surroundings. Emissions of ammonia, dust, and odour can have negative consequences for air quality and local ecosystems. InnoClean provides effective solutions to significantly reduce these emissions, tailored to the specific reduction goals of each business.

How does InnoClean work?

InnoClean air scrubbers operate by effectively bringing air into contact with water. The water is sprayed over a filter package, capturing harmful substances like ammonia, dust, and odour from the air. This process can be conducted chemically or biologically, depending on the required level of emission reduction.

The technology is flexible and can be adapted to various business conditions and scales. InnoClean air scrubbers are available in:

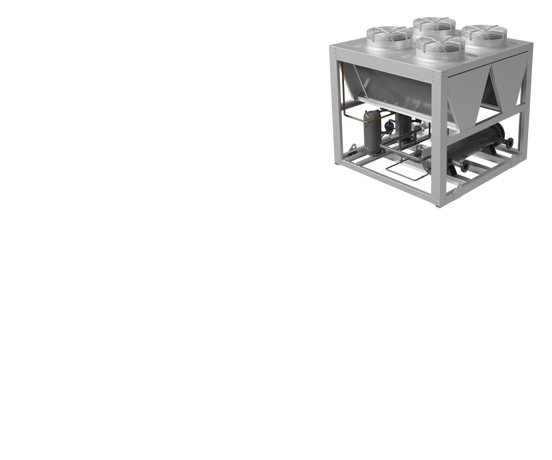

- Plug & play units: These complete units, including a technical room, can be quickly installed and are ideal for placement outside against the barn. Standard units can handle up to 150,000 m³ of air per hour. Multiple units can be linked and combined with a single technical room.

- Custom architectural solutions: For larger installations or situations where a standard unit is not suitable, InnoClean offers bespoke architectural solutions that integrate seamlessly into the existing infrastructure of the business.

With Synergy+, optimal barn conditions 365 days a year

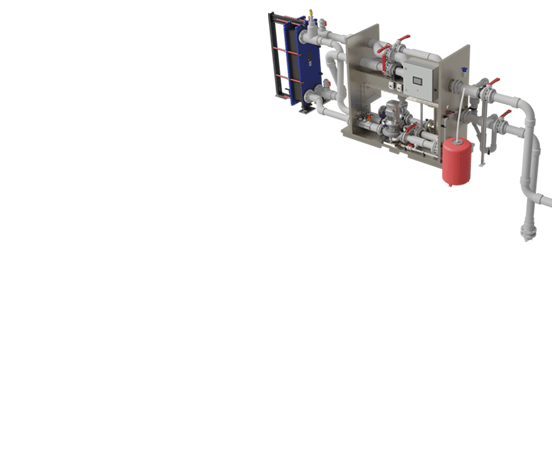

By combining InnoClean, InnoHeat and InnoCool, you are guaranteed a constant climate, 365 days a year. This integrated approach ensures optimal barn conditions, allowing your animals to perform under the best conditions. Smart cooperation between all systems helps you save substantially on energy costs. Heat exchangers in the air intake system provide heating in winter and cooling in summer. The air scrubber efficiently recovers heat from the stall air, allowing you to create an ideal climate at the lowest cost. Vital and healthy animals perform better, which benefits not only your bottom line, but also your job satisfaction.

- InnoClean – Reduces emissions and improves air quality.

- InnoHeat – Uses heat recovery systems to reuse energy, reducing your energy costs.

- InnoCool – Controls the temperature in the barn, prevents heat stress and improves the productivity of your animals.

Together, these systems provide the ultimate balance between energy efficiency, animal welfare and environmental responsibility. Synergy at all levels!

Eliminating outside stress influences

Minimizing inconvenience to the environment

Maximizing energy recovery

Key benefits of InnoClean

- Effective emission reduction: InnoClean drastically reduces emissions of ammonia, dust, and odour, improving both environmental impact and local air quality.

- Chemical or biological systems: Depending on reduction needs and specific conditions, the air scrubber can operate on a chemical or biological basis, providing a flexible and tailored solution.

- Control and monitoring: All InnoClean air scrubbers are equipped with a data logging system to continuously monitor performance. This enables timely interventions in case of deviations and ensures reliable operation, useful for reporting and compliance.

- Sustainable and efficient: By leveraging advanced emission reduction technologies, InnoClean promotes sustainable business operations and helps businesses comply with strict environmental and emission standards.

With InnoClean, you have not only a reliable solution for emission reduction but also a system that grows with your business, providing tools for environmental responsibility and cost-effective emission management, contributing to a sustainable future for your business and the environment.

We energise farming

Want to know how much you can earn with our Synergy+ technology?

Biological air scrubber: natural degradation of emissions

A biological air scrubber uses bacteria that break down pollutants naturally. The polluted air in the barn passes through a washing package. This is sprayed with water. As a result, substances such as ammonia, odour and fine dust are absorbed.

Bacteria grow in the process water and on the filter material. These bacteria convert substances into harmless compounds. Examples are nitrate and carbon dioxide.

For a stable operation, good system management is essential. Parameters such as pH, temperature, oxygen content and water flow must be kept within certain limits. This is necessary for a proper biological process.

The used wash water is periodically discharged or purified. The cleaned air leaves the air scrubber via an exhaust duct.

Chemical air scrubber: stable performance for maximum reduction

A chemical air scrubber removes pollution from the air. The process involves an acidic liquid, often made of sulphuric acid. The polluted air comes into contact with this liquid via a spray system. Ammonia and odour components are thus absorbed from the air.

The ammonia reacts with the acid to form ammonium sulphate, a harmless substance that remains in the wash water. The pH value of the washing liquid should be between 3 and 4. This ensures an efficient cleaning process. Regular adjustment with acid is necessary in this process.

As with the biological system, the used wash water is periodically discharged or purified. The treated air flows out of the system through a drainage channel.

Pig farming

Reduces odor and ammonia, improves air quality and ensures a healthy living environment.

Poultry farming

Optimizes airflow to reduce odor and particulate problems.

Cattle farming

Creates a stable and healthy climate while minimizing harmful emissions.

Insect farming

Improves air quality and optimizes the growing environment by reducing odor and dust particles, resulting in higher yields and more efficient production.