Insect farming

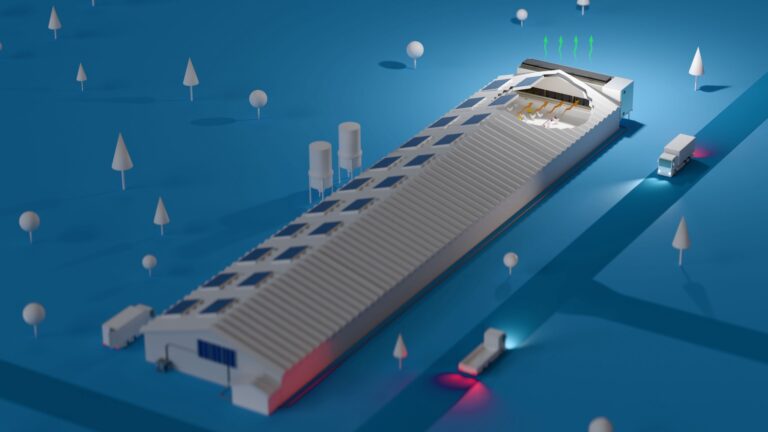

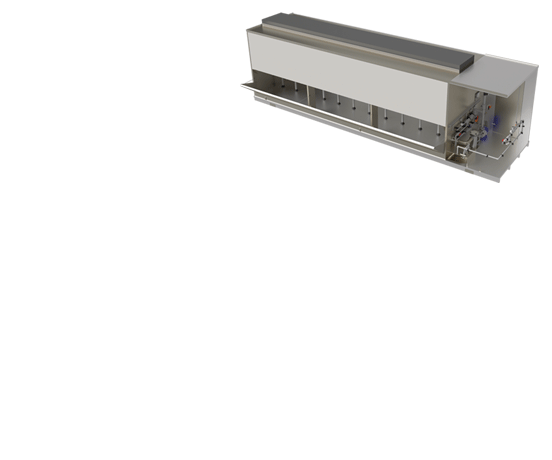

Synergy+ for insect farming

The Synergy+ approach from Inno+ is specifically tailored to the needs of the insect farming industry and focuses on three key pillars:

-

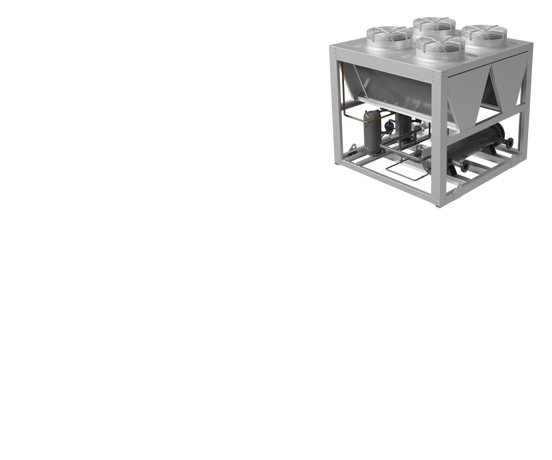

- Creating a stable living environment

Insects are sensitive to fluctuations in temperature and humidity. Our solutions ensure a stable, precisely controlled climate, resulting in higher productivity and lower loss rates during breeding.

- Creating a stable living environment

-

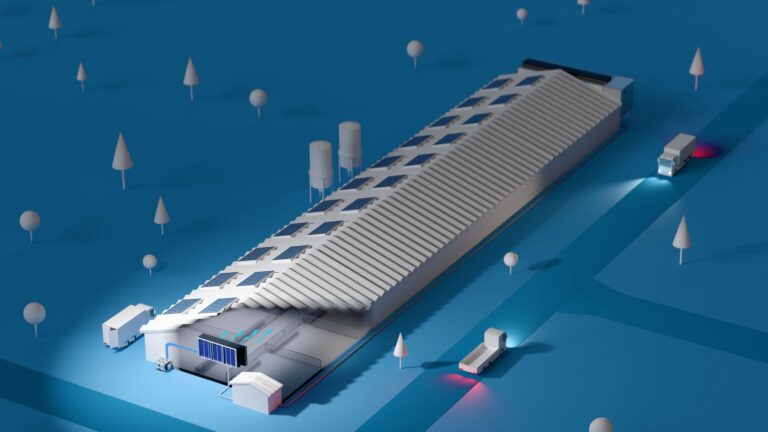

- Minimising environmental nuisance

Emissions of odour and other gases can be a challenge in insect farming. Our advanced emission reduction systems help limit emissions, ensuring your business meets the strictest environmental standards and minimises nuisance to the surroundings.

- Minimising environmental nuisance

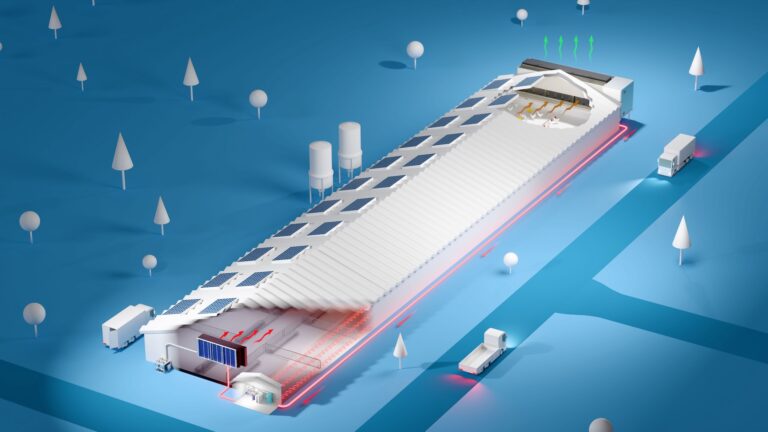

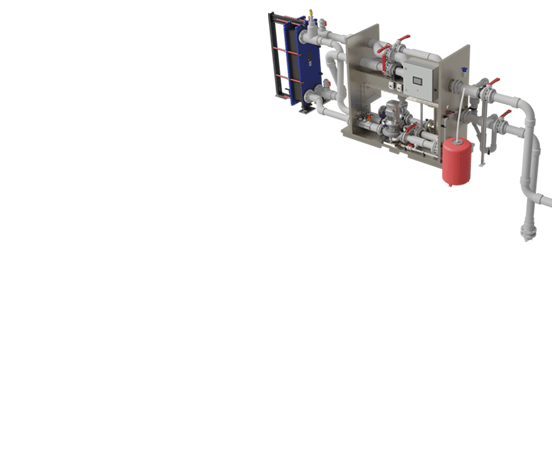

- Maximising energy recovery

Insect farms require constant temperature and humidity control, which can consume significant energy. Our systems recover up to 90% of the heat, leading to substantial energy savings and lower operating costs.

By combining these three pillars, Synergy+ offers a complete solution for insect farming that brings together energy savings, climate optimisation, and emission reduction. This not only makes your business more efficient but also future-proof and sustainable.

Limiting stress influences from outside

Reduce environmental nuisance

Preventing energy loss

We energise farming

Want to know how much you can earn with our Synergy+ technology?

Pig farming

Optimizes climate, reduces emissions and energy consumption, increases productivity and improves welfare of pigs.

Poultry farming

Improves air quality, regulates temperature and reduces energy costs, leading to better animal performance and health.

Cattle farming

Creates stable barn climate, reduces energy costs and promotes cattle health and productivity.

Manure processing

Optimizes climate, reduces emissions and energy consumption, increases productivity and improves welfare of pigs.