Another Porcus air scrubber has landed in Belgium

In early 2020 Belgium Pig farmer, Geert Schevenels from Zoutleeuw approached Inno+ with the intention to install a Biological air scrubber on his farm. After consultation with our consultant Mischa Hermkens, it was agreed a spilt solution would be best. Due to the flexibility in the Inno+ modular approach, it meant we could use our master/slave set up to service both buildings. Installing an air scrubber on the newly built sow house (master) as well as the existing finisher house (slave). This not only allowed Geert to extend his current production, but also future proofed the existing house against any changes in regulations. At the end of the day, not only doing the right thing for the environment, but also his business.

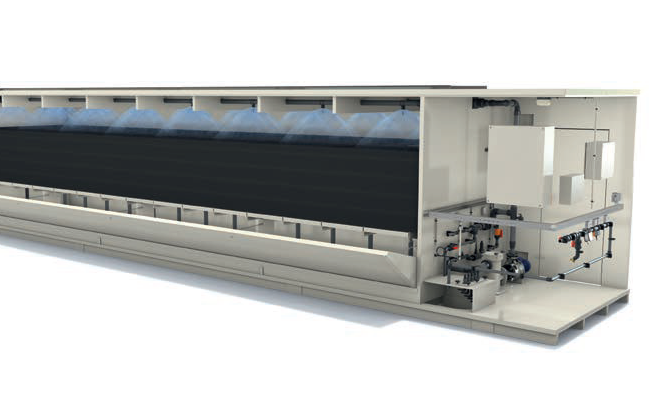

Porcus module, efficient design, lower operational cost

The choice for our Porcus module brings many benefits. Knowing the unit is designed and built in accordance with the Dutch BWL 2008.01.V3 certificate that achieves an ammonia reduction of up to 85%, dust of 70% and odour around 45%. This gives farmers the comfort of knowing our technology brings some guarantees on air abatement. The fact our system is designed using a slightly bigger filter area also means lower resistance, energy consumption and therefore less operational cost.

Master – Slave, one pump, two units

For installation, the master module was placed at the rear of the sow house of 360 pigs and will clean 60,000m3/h. The slave module was placed at the side of the finisher house with 1150 pigs, which will clean 92.000 m3/h. Combining air scrubbing for both houses in this way will reduce energy consumption and be better for the immediate surroundings.

Our master and slave units are supplied with water by means of one pump. This design ensures that the capacity of the pump is used optimally. Also making it possible to supply the slave module with washing water from a distance of 50 metres.

Installation, commissioning and training

This month the air scrubber was put into operation by our service department. This work involves a site visit where our engineers makes sure everything is connected properly. Leak detection done and once the system is eventually fired-up the site acceptance test is completed. Confirming not only all the tests we made in the factory are still good, but also and more importantly the system is running well on site. Once tests were completed and the unit was ‘signed off’.

User training is critical for good air scrubber performance

Our engineer then showed the customer how to operate the air scrubber and talked him through the finer points of how the biological process works. It will be some weeks before the bacteria has been allowed to grow and the system is operating 100%. At this early stage in the process, it is important the customer and his staff are trained well enough to make sure nothing is done to affect this process. Also that they know how to monitor the system, make any adjustment when necessary and ensure maintenance remains at a minimal Another advantage of our module design is that inspection is possible without switching off the air scrubber.

Remote monitoring from the cloud

An internet cable was also connected. This provides a link to the cloud where data from the system can be logged 24-7 and remotely monitored via an online visualisation.

The visualisation shows the Alarm status, pump status, pH value, electrical conductivity and water meter counters. With this information, it is often possible to assist with issues the farmer may be having and give advice remotely based on live data.

Download the Porcus dashboard report

In conclusion the farmers was very pleased with the way the project was executed and if looking forward to good results from these two units.

More information about Porcus, other air washers and Inno+

The Porcus series air scrubbers are specially designed for ease of transport and installation around the world. This means in countries where the licensing authorities are trying to set a benchmark for air cleaning on farms. Inno+, deliver a product with 18 years of development, testing, certification and proven experience behind it.

Are you curious about the possibilities of our air scrubbers? Fill in the form below or contact us: +31 (0) 77 – 4657360