Air scrubbers for livestock farming:

“The optimal combination between animal welfare and economically sound management”.

Fam. Grefte from Sunbro

Fam. Grefte from Sunbro

It is a legal requirement in intensive livestock farming to reduce emissions of ammonia, odour and particulates in order to reduce the impact on the environment.

An air scrubber is the tool to help meet this requirement. The air that leaves the house goes outside through an air scrubber. During this journey, the air is cleaned so that the outgoing air contains a minimum amount of ammonia, odour and particulate matter.

Thanks to our certification, Inno+ can guarantee that the technology used results in a reduction of ammonia up to 90%, dust by up to 70% and of odour by up to 75%.

Furthermore our air scrubbers are plug and play. Thanks to its dimensions we can easily deliver the units anywhere in the world and your local installer can install the it within one day.

Our scrubbers works quite simply, but effective:

It is necessary to continuously control the quality of the washing water for maximum removal of dust, odour and ammonia. The two most important parameters that are monitored and regulated are the pH and the conductivity of the washing water. A constantly controlled pH is necessary to realise an optimal removal of ammonia and odour molecules. The regulation of the conductivity is necessary to regulate the desired maximum nitrogen content in the washing water. In addition, several other processes are controlled and measured to ensure optimal performance of the air washer.

Watch the video for an idea of how the scrubber works, in combination with climate conditioning. The scrubber is used for various markets, such as pig, cattle and poultry farming and manure treatment systems.

The Triple EEE concept is a sustainable system for heat recovery. The purpose of the Triple EEE concept is to recover energy from the process water of the scrubber. This energy is then used to pre-heat the incoming air in the winter period. Another goal of the Triple EEE system is to improve the air quality in the house. Because more energy is brought into the house, more ventilation can take place and the relative air humidity, CO2 concentration and other harmful substances are reduced.

With the Triple EEE concept, with 1 kW of electrical energy for the installation, you can recover up to 77 kW of thermal energy from stall air for preheating the incoming ventilation air. The Triple EEE concept realises a reduction in heating costs up to 60%. In combination with a heat pump for post-heating, this results in a total cost saving up to 87%.

There are two different types available:

Our biological systems use micro-organisms in the scrubber water to reduce ammonia and odour from the houses. This leads to maximum 85% ammonia reduction, 75% odour reduction and 70% particulate matter reduction.

These reduce ammonia and odour by adding sulphuric acid to the wash water, which lowers the pH and absorbs the ammonia. This leads to an ammonia reduction of 70 to 95%, an odour reduction of 30% to 40% and a fine dust reduction up to 87%.

Our systems have several advantages that might be interesting for you.

The scrubbers are highly efficient and easy to maintain and regulate.

The real-time data registration system can be continuously monitored from a central location by our technical team to ensure the optimal performance that was agreed upon. This enables our clients to react to changes at their company and repair any problems that occur, so that they can continuously meet their emission reduction targets.

Data registration also creates the possibility to add the data of the air scrubber to the other data collected in the farm. This makes our products a valuable tool to meet your smart farming goals.

General

Other

Modular construction

Minimum area calculations based on the following

Example – With a volume flow of outgoing air of, for example, 300,000 m3/h the results are as follows:

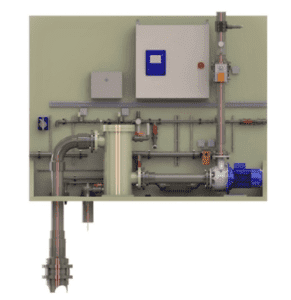

Skids

A skid is a specially built frame for equipment, in this case for the technology to drive the air scrubber.

Module

A module is a complete prefabricated air scrubber in a plastic housing.

Due to air capacities it is recommended to use built-in air scrubbers for poultry instead of modules, because of practical aspects regarding dimensions.