‘Two-steps’ forward in insect production

This month our construction team under the supervision of our international service manager Grant Barden attended a site in Hedensted, Denmark to install and commission our first insect project. This was for Enorm BioFactory; a company that has the ambition to develop a scalable concept for the production of Black Soldier fly larvae globally. Inno+ are, together with group sister companies, working to help them realise this ambition.

To learn more about the projects, CEO Carsten L. Pedersen tells about the industrialization of the Black Soldier Fly Larvae production at the Enorm Bio factory >>

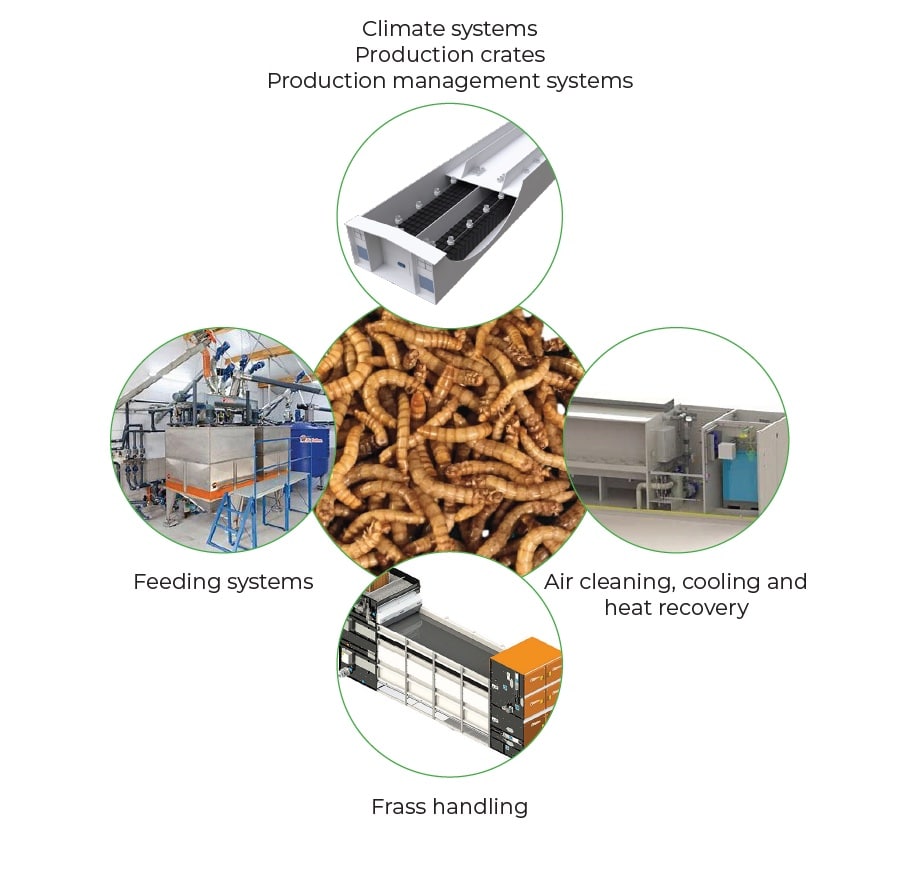

Turnkey concept

The project involved setting up an air scrubber and energy recovery module for their pilot site. This is the first of several projects we are working on, to deliver turnkey systems from the insect group’s portfolio for various customers. For these we offer a complete concept that includes climate, production crates, feeding systems, air scrubbing, energy recovery, cooling, frass handling and production management systems.

Pilot production

In Hedensted, the pilot site is capable of growing 10-12 Tons of larvae per week. The total air capacity required for cleaning is 40,000 m3/h with an air input quality needed at 30 degrees C @ 70% humidity, delivering an overall enthalpy of approximately 80. This would ensure optimal conditions for production.

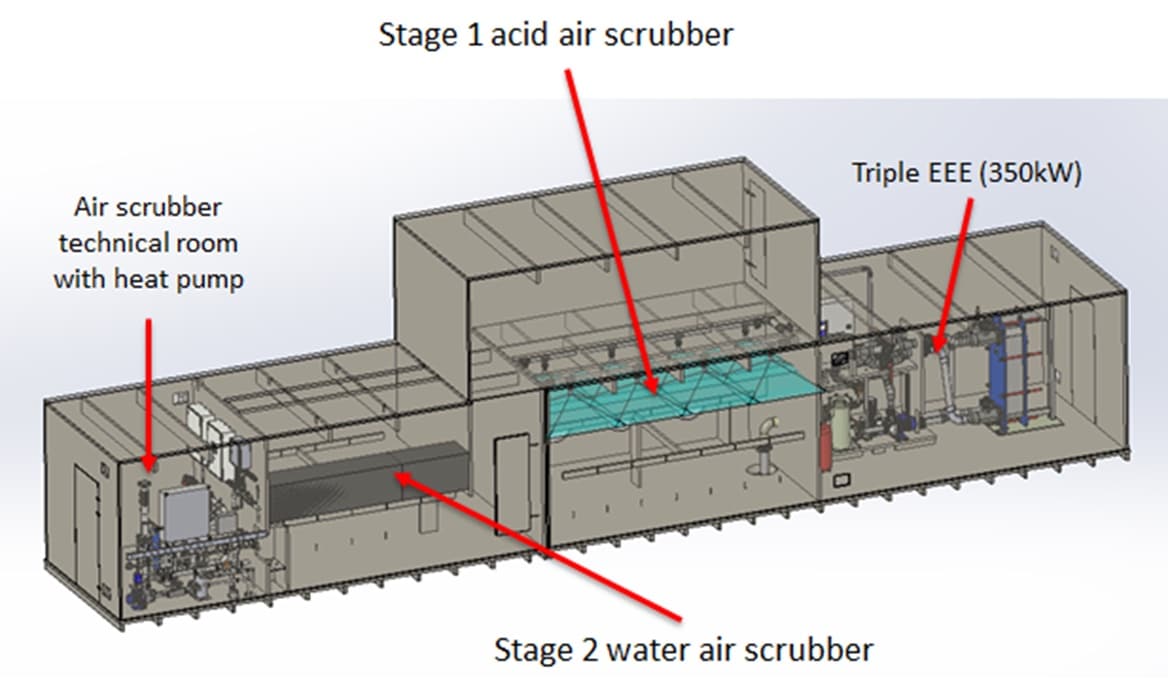

Two stage air scrubbing and energy recovery

Inno+ delivered a two-step air scrubber and energy recovery system.

- The first stage involved a chemical air scrubber designed to lower emissions of max 40,000 m3/h air from 50 ppms ammonia down to 2 ppms. This was a requirement set out in the planning due to environmental restrictions. Connected to this first air scrubber is our triple EEE energy recovery system built to deliver 300 kW of energy, so that during the cold periods we can bridge the gap by heating up to max 30,000 m3/hour from -10 to +20 degrees C using thermal energy from all the rooms. Triple EEE is a very efficient way to deliver lower levels of thermal energy to house

- The second stage involves a water air scrubber with a heat pump attached delivering 120 kW of energy. This second heat stage makes sure that the pre-heated air reaches the required climate condition for the larvae.

- The water scrubber, apart from gathering energy, has the additional benefit of ensuring no acid droplets leave the system and offers additional odour reduction. Both systems are connected with a hood or top section that steers the air from one to the other.

Pre build and tested before shipping

The whole concept came as prefabricated modules that were built and tested in the Inno+ factory before being shipped. The advantage of this approach is that by pre testing we can iron out any issues before the units appear at the customer location and the module design means that installation and commissioning can be carried out with minimum onsite work in a timely fashion. This is an important part of our overall strategy to deliver air scrubbing globally for pigs and poultry.

For more about systems from Inno+:

Global presence

The sister companies of the insect group collectively have a global presence with, 48 regional offices and +200 dealers and service partners. We offer production consultancy, site design, lab and field testing with of course our own manufacturing and service support. For more information about the our insect group concepts please contact:

Henrik Voight

E-mail: hvo@skov.dk

Telefoon: +45 22 71 25 71

Linkedin: https://www.linkedin.com/in/henrikvoigt/