Triple EEE ICE+ training

This week we received our very first Triple EEE ICE+ trained technicians from our dealer Versleijen, Oirlo in the Netherlands.

We started the day with a tour of our factory and the specialist construction equipment we use to build the Triple EEE system. Also meeting our production team and seeing exactly how we produce the Heat Energy Recovery System first hand. For more information about Triple EEE, please follow this link https://inno-plussystems.com/en/products/triple-eee-heat-recovery-system-for-stables/

With a coffee in hand, we began the presentation. This was firstly an introduction into INNO+ as a company but more importantly, our ethos. We strive to reduce the impact on the environment by making a stall as efficient and economical as possible.

Efficient, Economical, Environment…Triple EEE.

With a clear understanding of what we are achieving with the system and why, it was time for the ‘how’.

Our International Service Manager Grant Barden delivered a series of three modules:

“How the Triple EEE system functions, Operation and its capabilities”.

The system is designed to recover heat energy from wash water in the air scrubber. This heat energy transfers from the outgoing stable air to the process water as it passes through the shower until and washing table. Triple EEE uses this heat energy it to condition cold incoming air, reducing the cost of temperature control system in the stall.

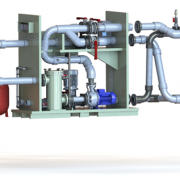

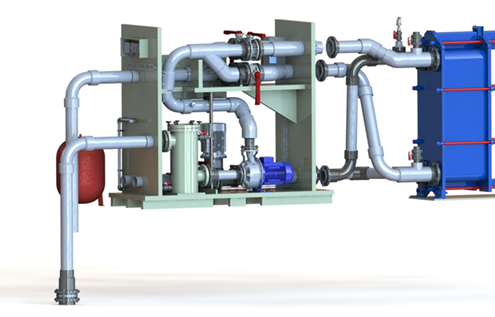

“Component Parts and Installation”

A clear run down of the parts used in the system, what do they do and how to build them in. Over the course of the presentation, the team learned about all the different parts of the standard system. It was clear to see this information being soaked up. Questions raised by the team showed they were keen to get as much from the training as possible.

“Start-up and maintenance”

Delivered with the system is with a Technical Dossier containing the start-up and test procedure, the maintenance checklist and the technical specification. With copies of this to hand, the team were guided through how the procedures are completed and recorded.

With a firm grasp of the system, there followed a demonstration of the IXON remote monitoring application. This included Data Recall, extracting data from the system, user interface, graphs and remote access to control the system interface screen.

After lunch, the team continued with a practical session by one of our flagship clients in Grubbenvorst. This gave the team the opportunity to put into practice the new things they had learned. Each member of the team logged into the system and performed tests, checks and adjustments across the different subsystems. Seeing the team working and adjusting the system was very satisfying, knowing that there are now ICE+ Versleijen technicians in the field and ready to support Triple EEE systems.

For more information about ICE+ training please contact Grant Barden – gbarden@inno-plussystems.com