Online air scrubber technical training for Big Dutchman engineers

In a world under lockdown, ‘in person’ training sessions have become a challenge. That said, the show must go on and with the increased interest and installations of our air scrubber technology worldwide, business must continue as normal as possible.

Embracing technology

Part of our ‘digital’ strategy at Inno+ is to embrace technology throughout the business also applying it to our online training. Apart from video conferencing tools to communicate and hold meetings we have also taken advantage of 360° camera technology to give our audience as close to an onsite experience as possible, in the form of virtual tours. Those that have access to virtual reality headsets can even go as part as having the experience of standing in our systems and looking around.

360º images

When the technical team in Germany requested training. We set up a webinar to share our knowledge with them from the comfort and safety of their own homes. The training consisted of series of presentations and discussion with our International Service Manager Gant Barden, where he shared first hand practical experience of installing and supporting our systems.

Introduction to Air Scrubbing

What is air scrubbing? How does it work? With a presentation, it is not as easy to show how an air scrubber works compared to standing inside one. That said, we laid out the principals of operation for both our Chemical and Biological Air Scrubbers. A short science lesson on how Ammonia is dissolved in water to be either, bonded with Sulphuric acid or nitrified by bacteria….and of course some 360 images to take a digital look around.

For more information on the Biological and Chemical Air scrubbing process you can download white papers on these subjects.

Component Parts

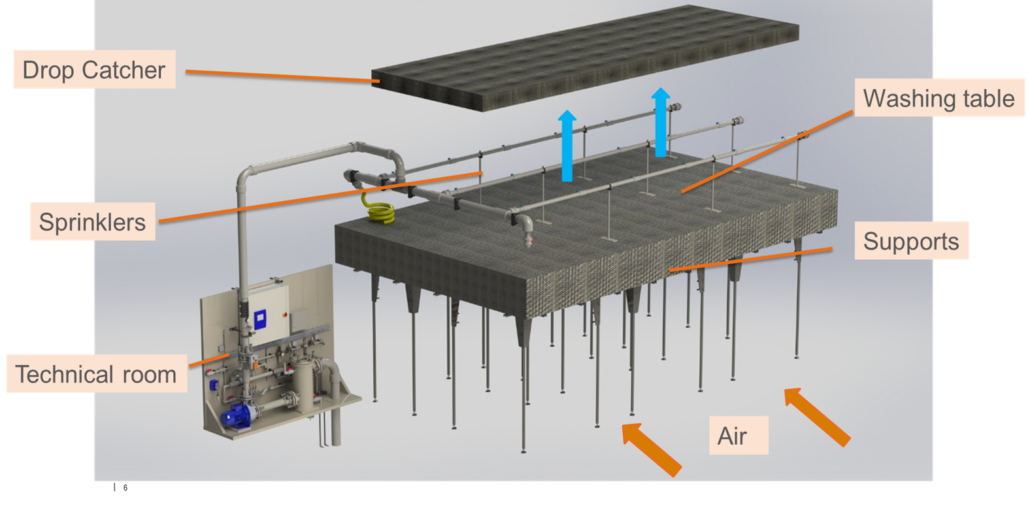

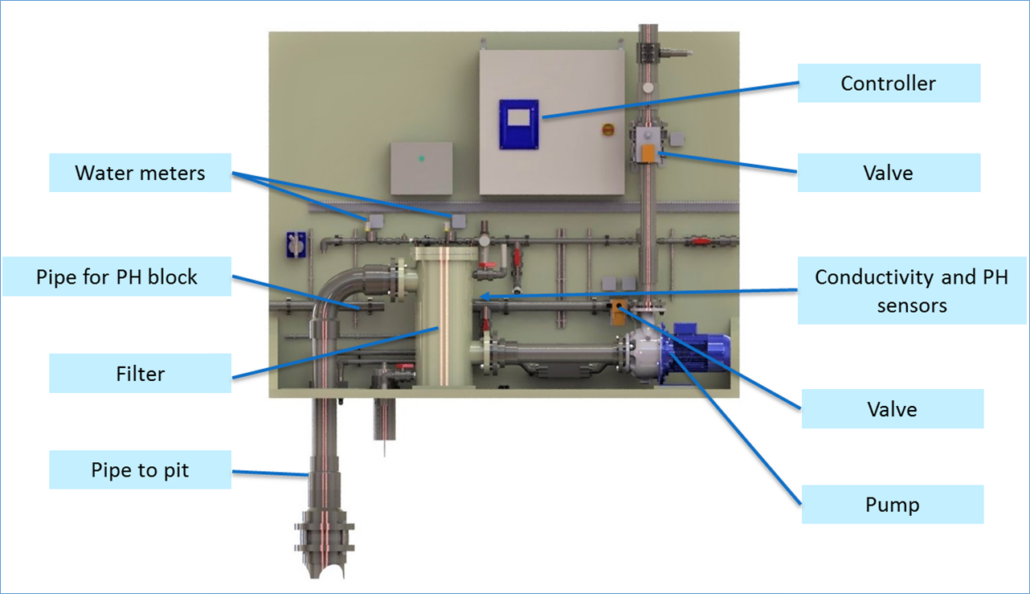

What models are available and what are the main parts they use? The system is made up of a series of components from Pumps to Sensors. Going through these one by one, we discussed the individual working of them and their purpose within the system.

The Level Sensor and Minimum level Float switched need to be made to the right length for the project.

The Flow Meter in the Pressure line and the Main Restrictor Valve in the line need to be adjusted later during comissioning, The pH Sensors and Conductivity Sencors will be regularly cleaned by the user so this needs to be clearly explained on site how they are removed, cleaned and reinstalled.

Installation

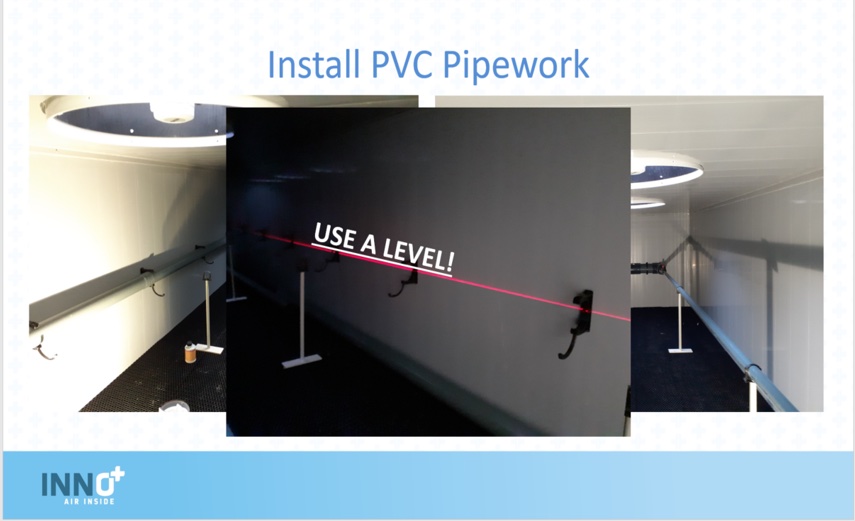

How do we build an Air Scrubber on site or connect a module? What do we connect and where? Building an Air Scrubber is not just one, 2, 3! This portion of the presentation we discussed the way we build, delivered materials and how the technology is assembled on site. Emphasising doing things in the right order. Firstly building and levelling the Stainless Steel Table, what parts go where and how to level it once assembled. Loading and stacking of filter packages. Building of the pipework distributing the water to the sprinklers and finally, the installation of the Technical Room with all the components.

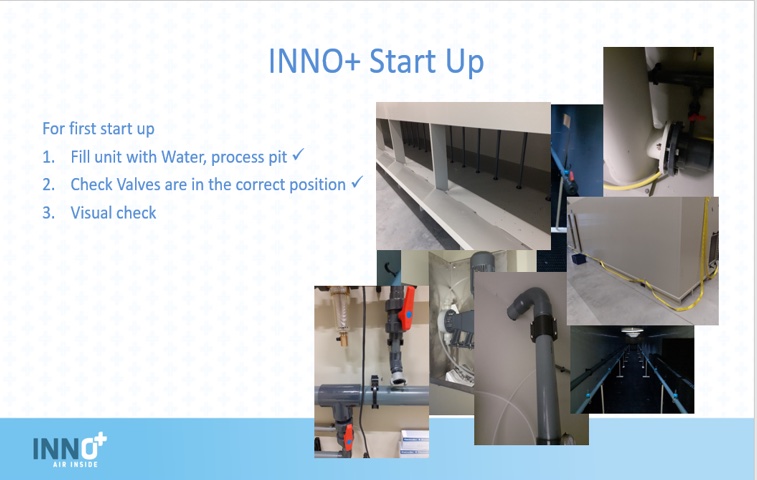

Commissioning

Factory Acceptance Testing, FAT and Site Acceptance Testing, SAT? Factory testing the Air Scrubber before delivery to the client ensures high quality control, each unit rigorously tested in our purpose built facility. Starting up and Site Acceptance Testing is done as part of the commissioning process, every subsystem is adjusted and tested live. Monitoring the system running to confirm performance then simulating faults to check the protection settings of the controller. What do we teach the client? The SAT gives a technician time to demonstrate operating the system and practice User Level Maintenance.

Attendees scribbled down the instructions as this was explained showing that we were reaching the audience. Starting up the system, adjusting it to run correctly, placing it into service and recording it all along the way.

Service and troubleshooting

What is a service in an Air Scrubber? We discussed Maintenance at both user and technician level. For example, to ensure correct performance of Air Scrubbers, the pH Sensors are replaced every year then calibrated every 6 months. We presented and discussed this process.

A certain amount of the maintenance performed on Air Scrubbers is User Level, meaning, the user maintains their own system for the small things preventing large issues developing. Cleaning of filters, sprinklers and sensors will keep the system running better saving on resources, down time and repairs.

Conclusions

After the two and a half hours of presentations, discussion, questions and answers. Our colleagues felt they had a good grounding in the principles of air scrubbers and a better idea of what is involved when installing, commissioning and supporting the technology.

All agreed that hopefully in the near future we would be able to meet in person at a live site and put this knowledge into practice.

More information about our air scrubbers, and other technologies from Inno+

Our modular air scrubbers are specially designed for ease of transport and installation around the world. This means in countries where the licensing authorities are trying to set a benchmark for air cleaning on farms. The Big Dutchman group can through its daughter company Inno+, deliver a product with 18 years of development, testing, certification and proven experience behind it.

Bent u benieuwd naar de mogelijkheden van onze luchtwassers? Vul onderstaand formulier in of neem contact met ons op: +31 (0) 77 – 4657360