First Porcus delivered, installed and commissioned in Italy….and we didn’t ‘blow the doors off’

This month our international service manager Grant Barden visited the Venice region in Italy to commission the first Porcus air scrubber. Prior to the visit our Italian colleagues had already installed the unit with pH stabilisation. The other goal of the visit was to provide training to the customer and our local team in the finer points of air scrubbing.

Good factory preparation is key

With careful dimensioning, our Porcus Air Scrubber is produced for transport in a standard forty-foot shipping container. Its prefabricated design means the modular system can be Factory tested before it arrives on site. Minimal ‘last minute’ adjustments or fixes means reduced installation cost and limited risk of failure during final site testing. With 4000 pigs in the stall, this air scrubber will have its work cut out. Over the next six weeks, two bacterial cultures will grow in the Air Scrubber package. The first will Nitrify Ammonia in the exhaust air. The second will oxidise the Nitrites into Nitrates. The fact we are able to prepare early and focus site commissioning on the finer details, means this biological process has the best chance of running optimally after the 6-week period.

Top marks for a great install

On visiting the site and conducting the first inspection, Grant reported that top marks must be given to Big Dutchman team for such a good installation. The instructions were followed to the letter and the module was perfectly mounted at the end of the building. The pressure room was nicely finished and sealed to the highest standard. This meant work could begin quickly with mechanic, Giuseppe and salesman Niccolo (who was keen to learn more about this new technology and how it works).

The first task was to install the pH stabilisation system

This consists of two chemical pumps in individual housings with leak detection sensors. After a quick discussion, we hung the pumps, fitted the 32mm PVC pipework and inside that, PTFE and LDPE hoses required for the low and high pH values respectively. Running the chemical hoses inside PUC pipe provides the hose with protection from damage and contains the chemicals in the event of a hose failure. At the injector we fitted a pull relief cover that bolts onto the connection and seals with a gland. This prevents the hose working loose as the pump pulses chemicals through but also prevents the hose being accidently pulled off. With the pipework complete from the injectors to the pickup lance, we connected the power cables and alarm signals securing all cables tidily in cable tray.

Leak detection

For testing, we primed and injected the system with clean water. We do this to check for leaks. Of course, it is far safer to use water should a connection still be loose. Water is also thinner than the chemicals used therefore will expose smaller leaks faster.

With the pumps now working, we tested each of the leak detection sensor multiple times to ensure that should either pump develop a leak in the future, an alarm is shown in the technical room and the pump immediately deactivated.

Site acceptance test

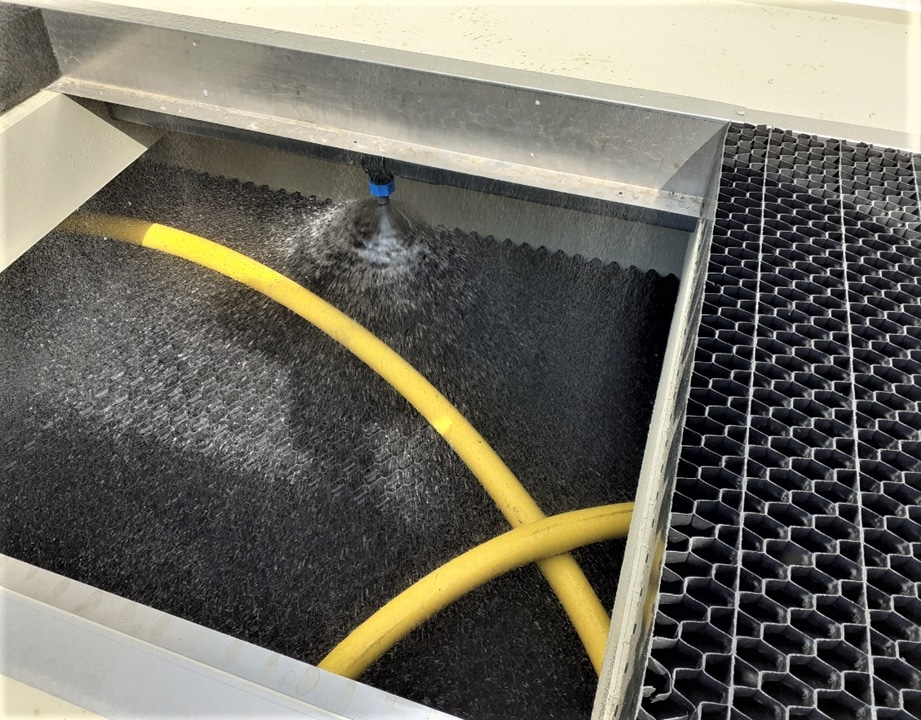

So, there it is. The unit is in, the power, water and waste all connected. It was time for the magic moment. The main power switched on and with a press of a button, Italy’s first Porcus air scrubber came to life. Over the next hour the team carried out the Inno+ Site Acceptance Test or SAT for short. At the heart of the air scrubber system is the main water pump providing a continuous circulation of the process water. First, we test for simple yet critical points. Is the pump turning the right way? Are there any leaks? After this, some more in depth tests. We confirm the pump is performing hydraulically with sufficient flow at the correct pressure. Typically, we have 0.5bar of pressure at the sprinklers but, the larger the air scrubber, the more flow is required. We also need to ensure the pump is not working too hard to do this. By testing the Voltage and amperage, we can confirm the power used by the pump.

After this, we can move on to testing individual components and their automatic functions. For example, we calibrate the pH sensor to ensure the controller will display the correct value at all times. We then use low and high pH solutions to trigger the activation of the Acid and Alkali pumps respectively. We trigger the water level detection assembly to ensure that all valves open and close as intended.

We also simulate all emergency situations to ensure all alarm systems function correctly and protect the system.

Remote monitoring from the cloud

The internet cable was also connected. This provides a link to the cloud where data from the system can be logged 24-7 and remotely monitored via an online visualisation.

The visualisation shows the Alarm status, pump status, pH value, electrical conductivity and water meter counters. With this information, it is often possible to assist with issues the farmer may be having and give advice remotely based on live data.

Download the Porcus dashboard report

User training and a happy customer

Once happy with the air scrubber performance, we showed the client through the system, advising on operations and user level maintenance. This was an interesting conversation as neither the client or Grant speak a common language. Niccolo stepped in to work as a translator providing an essential link between Dutch, English and Italian. Working together, Big Dutchman Italy we have delivered a quality product and an outstanding installation. The client is happy and is already asking for the system to be integrated into his other stalls.

More information about Porcus, other air washers and Inno+

The Porcus series air scrubbers are specially designed for ease of transport and installation around the world. This means in countries where the licensing authorities are trying to set a benchmark for air cleaning on farms. The Big Dutchman group can through its daughter company Inno+, deliver a product with 18 years of development, testing, certification and proven experience behind it.

Are you curious about the possibilities of our air scrubbers? Fill in the form below or contact us: +31 (0) 77 – 4657360