Eco-friendly energy model reduces energy consumption by 38%

Danish insect producer, Enorm Biofactory, has received the second part of the DKK 370 million funding program (USD 48,5 million) that the company raised in January, and also brought DLG into the circle of owners. The fund, which was raised through an agreement on additional equity, convertible bonds, and a loan program, has now been increased since the owners have contributed with more funds, and the Danish Green Investment Fund and Nykredit Bank have expanded the loan amount. This enables the producer to continue expanding its plant.

Switch to eco-friendly energy model

The initial project, under construction in Hedensted, Denmark and expected to be in full production by the end of 2023, was powered by natural gas. Since the energy market changed in 2022, the plan has changed, and the new fund will be utilized to switch the production to an eco-friendly energy model. “A lot has happened in the world since the project was announced, and energy prices and construction costs have skyrocketed. Therefore, I’m pleased that we have an investment group that is 100% behind us and that even allows us to invest in more sustainable energy sources than what was originally planned,” said Carsten Lind Pedersen, Enorm Biofactory’s CEO. “The first phase of construction is close to completion, which means that we can soon increase production at our pilot plant, which is already in operation.”

Reduce production costs with sustainable energy solution

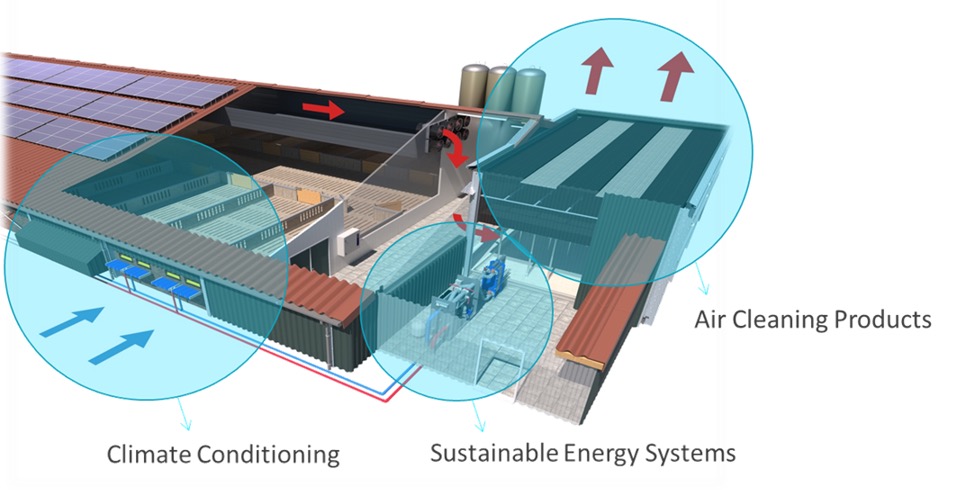

The new sustainable energy solution, that will secure the reduction of Enorm Biofactory’s production costs, will have a new boiler station that can use carbon-neutral biomass from wood chips, garden waste, fast-growing willow trees, and other sources of locally produced wood-based biomass. At the same time, the company has invested in a heat exchanger system to recirculate heat from the stables used for insect production. In combination with other optimized energy solutions, the heat circulation system is expected to reduce energy consumption by 38% in future production.

Reduction of emissions leads to energy saving

A key component of this new innovative solution, is the ability to harness free energy that would otherwise be lost into the atmosphere. By capturing the heat from the insect cells as it leaves the building, through an air scrubbing process. It is possible to reuse this thermal energy to pre condition the air as it enters the building. The system by Inno+ is called Triple EEE, which incorporates specially designed exchanger plates to transfer the energy from the dirty wash water to clean water. This can then be transported to any point where air pre conditioning takes place.

Megawatts of energy reused contributes to 50% of the total saving

With the considerable levels of energy involved eg. 4kW of energy produced for every m3 of floor space and a need to deliver around 30°C and 75% humidity, the potential for savings is massive on large scale insect farms. In this case over 6 megawatts of energy. Not only does this have a financial benefit, but it also means we keep the carbon footprint to a minimum. This means the Triple EEE system contributes to 19.9% energy saving.

The new facility will have a production capacity of 100 tonnes of larvae per day, corresponding to 11,000 tonnes of insect protein per year to be used as a protein source in animal feed.

More information about our systems

If you would like to schedule a no-obligation appointment to see what is possible to optimize your insect business. Please contact:

Henrik Voigt

Key Account Manager Insects

Mobile phone: +45 22 71 25 71

hvo@betterinsectsolutions.com