CompoTower Air Scrubber –

The new air scrubber for vertical composting solutions

An increasing numbers of livestock farmers are composting the manure at their farms. They do this to increase the value of their manure product and make it easier to sell. To achieve this they use composting towers. In Asia, we see large numbers of these units, but also in Europe, there is an increased interest in these solutions.

Composting towers

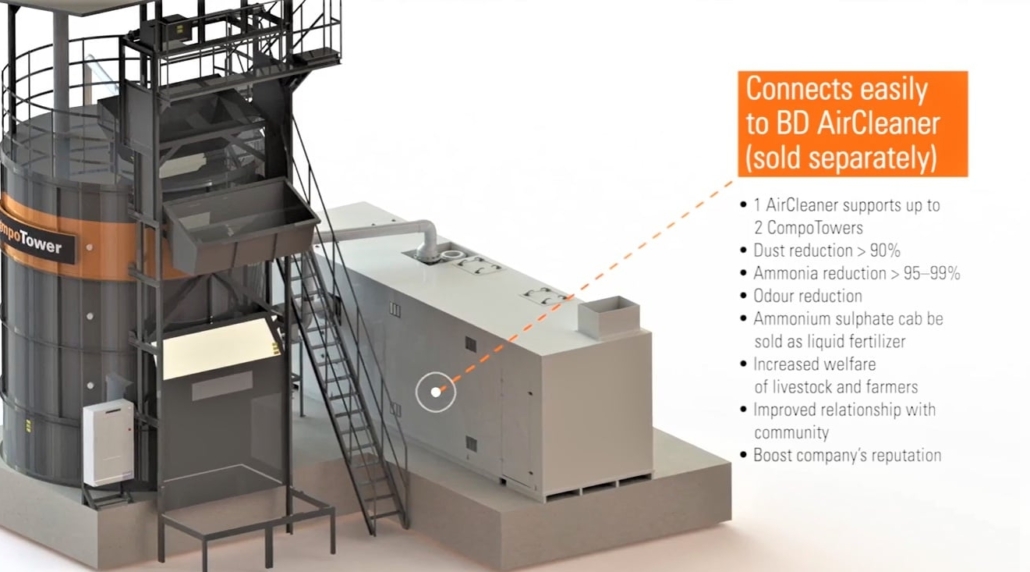

Are relatively simple solutions where the manure is added to the top of a ‘closed vessel’. Because it is closed there is very good control over aeration, temperature and hygienisation of the process. Resulting in valuable compost. Because of the obvious benefits, we see more and more commercially available installations to suit the size of your business. A couple of examples of these are the CompoTower and CompoLiner provided by our parent company Big Dutchman.

3000 to 30 ppm ammonia, a 99% reduction

These composting solutions produce ammonia-polluted air, in small volumes but with extreme high concentrations. For example, a CompoTower with 66 m3 of content produces 600 m3 of air per hour with ammonia concentrations of up to 3000 ppm. These emissions are very damaging to the environment and also very dangerous for people and animals in the neighborhood.

To address this emission problem, Inno+ has developed a special air scrubber that can deal with small volumes of high concentration ammonia, reducing emissions drastically. One CompoTower Air Scrubber can clean the air from two 66m3 or one 130m3 Composting tower. With an air input of maximum 1200 m3/h of polluted air, the output will then be 30 ppm, achieving a reduction of 99%.

Specifications of the CompoTower air scrubber

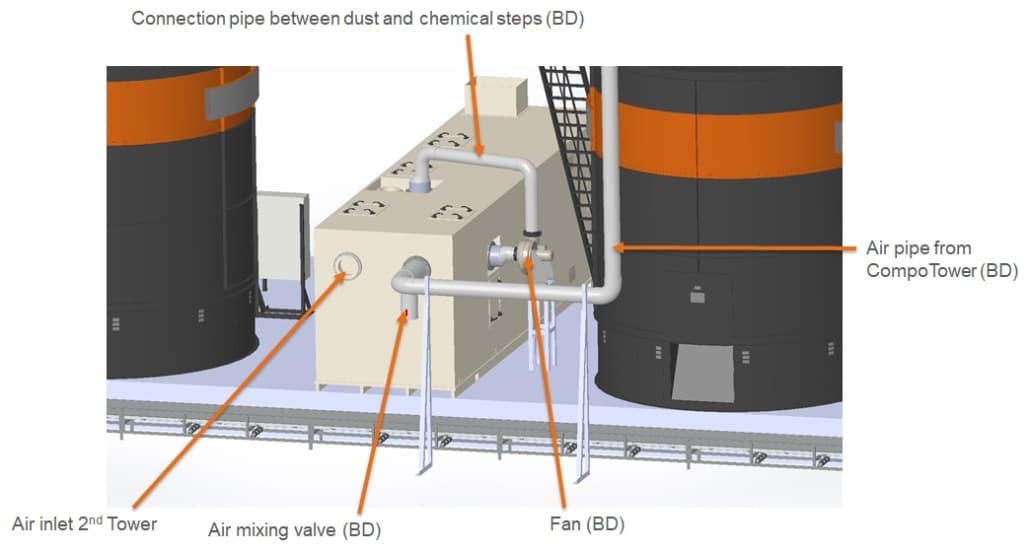

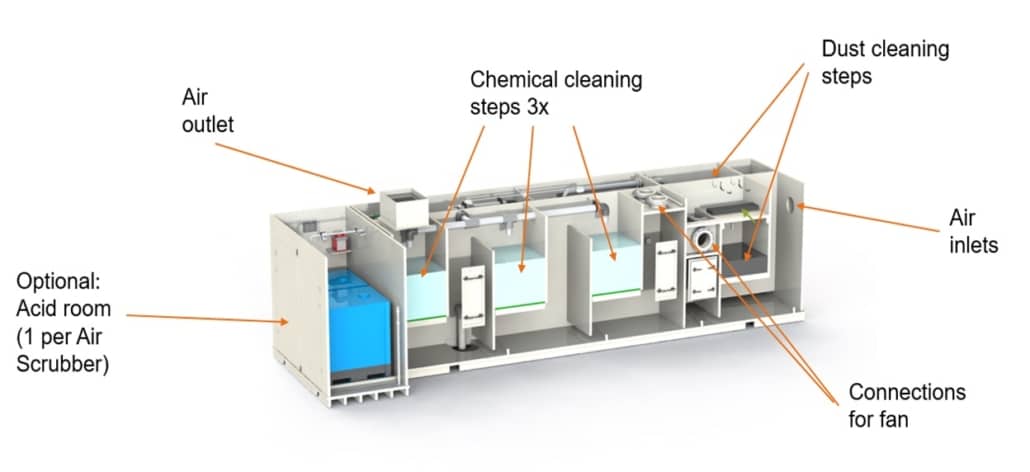

The CompoTower Air scrubber comes as a stand-alone prefabricated plastic container, fitted with a room on the side, in which all the scrubber technology is mounted. This makes on-site placement as quick and easy as possible. From there the air scrubbing process is then fully automated.

Automated process

- The polluted air from 1 or 2 composting towers is led through pipes and enters the scrubber at the front.

- Just before the entrance, fresh air is mixed with the polluted air to lower the temperature and reduce the ammonia concentration.

- Then the first washing step is started with water and no additions to clean out most of the dust.

- The air is then pulled out of the scrubber through fans and pushed into the second cleaning step, which consists of 3 consecutive chemically (acid) sprayed washing beds, for a very intensive washing of the air.

- The cleaned air then leaves the air scrubber at the top through a drip catcher that retains most of the moisture.

The result a safe level of exhaust emission that has a much lower impact on the environment.

Inorganic fertilizer

Another valuable by-product of this process is Ammonium Sulphate. This is produced because of the binding of ammonia in the air and the acid that is mixed to the wash water during the air scrubbing processes. Ammonium sulphate is an inorganic fertilizer that can used on the land. A combination of these two processes, composting and air scrubbing make this a truly sustainable solution for farmers looking to reduce their GHG profile.

More information about our solutions

For more information on the Inno+ air scrubbers or air scrubbing in general, please visit:

For more information, about manure and composting systems from our parent company Big Dutchman:

Are you curious about the possibilities of our air scrubbers? Fill in the form below or contact us: +31 (0) 77 – 4657360