From professional footballer to pig farmer

Since 1928, the Custers family has had a mixed farm in Swolgen, Limburg. Over the years, this farm has slowly grown into a beautiful pig farm. After his soccer career with VVV-Venlo, Gert joined the company in 1991. He exchanged his great passion for soccer and especially goalkeeping for the pigs. At the age of 25, Gert took over the family business and built it up to its current size. The company is now almost 100 years old and is looking forward to a bright future.

Business growth

The Custers family farm falls under the Varketing Group and has grown to 500 sows and 5,000 fattening pigs through an expansion in 2007 and a newly built fattening pig house in 2014. At both locations in Swolgen and Horst, Inno+ chemical air scrubbers and heat pumps have been installed. At the second one, we also included Triple EEE energy recovery. This eliminates the need for gas at both. Since the roofs are also full of solar panels, this makes the company’s production energy neutral. The heat pump uses the energy in the air scrubber where the water has a temperature of about 20 degrees. Because there is underfloor heating everywhere, the heat pump makes it easy to heat the stables, the whole house and even the family pool.

Inno+ Online reporting

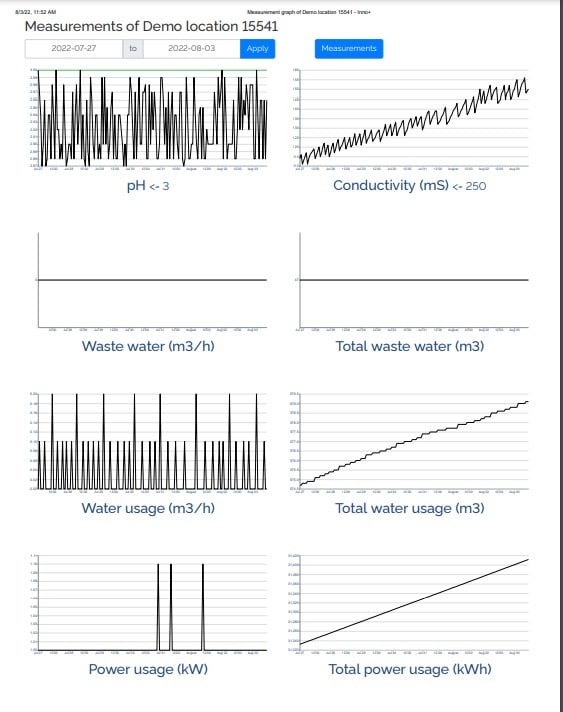

In 2022, we updated Gert’s system so that he has access to our online reporting tool. This means he has easy access to important data so he can check that his air scrubbers are working properly and make corrections when he sees that adjustments are needed.

Using the dashboard

Gert was always convinced that the air scrubbers were working well. Now that Inno+ sends the monthly reports, it appears that there is still some room for improvement. He is happy that he can clearly see what can be improved, because he wants his air scrubber to run perfectly, both for himself and for the environment! Another advantage of the dashboard is that the Inno+ service team can immediately see which activities are taking place in the air scrubber at a certain moment or can look back to the past. This makes everything perfectly monitorable and allows the client and/or Inno+ to react and adjust in time if necessary.

Monitor, Maintain, Perform

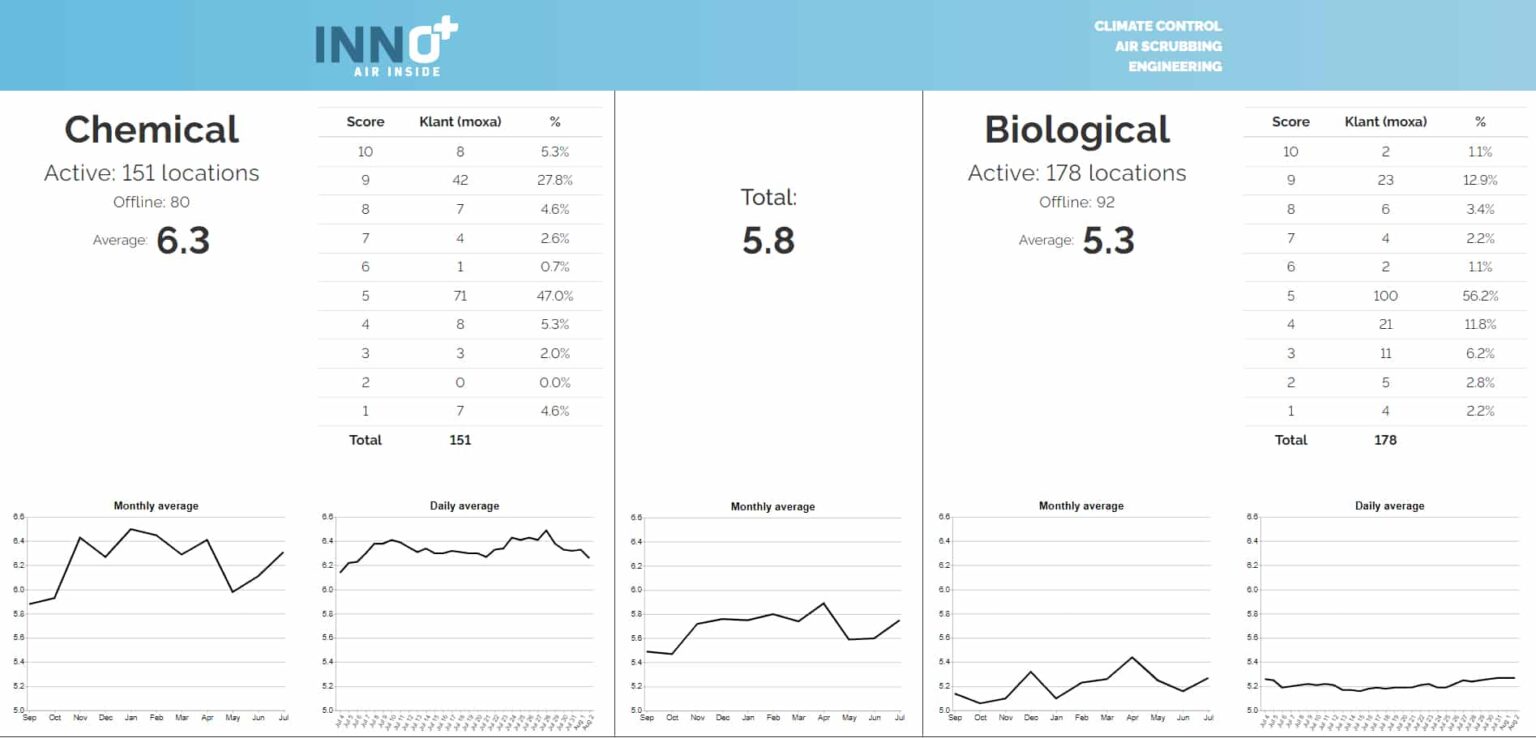

Over the past year, we have used our online system to monitor more than 300 sites in the Netherlands in real time. This is a mix of biological and chemical air scrubbers and pig, poultry and cattle farms. Even with our extensive knowledge from 20 years of supplying and supporting air scrubbers, we learn more about the process every week. This allows us to provide more value to our customers and ensure that the technology meets the objectives set forth in the permits. Perhaps the most important lesson we have learned: an air scrubber that is monitored can be better maintained and ultimately perform well.

Monitoring and maintenance - the key to future performance

One of the conclusions in a recent report from Wageningen was that for us, the challenges of emissions management of farms with air scrubbers. Regular monitoring will become necessary, even mandatory. By developing such a system that allows farmers to keep abreast of the process, we believe this is an important step forward in meeting the challenge.

Learn more about:

- Inno+ Air scrubbers

- Triple EEE heat recovery

- Online reporting

- Varketing group