Heat recovery from air scrubbers in Belgium

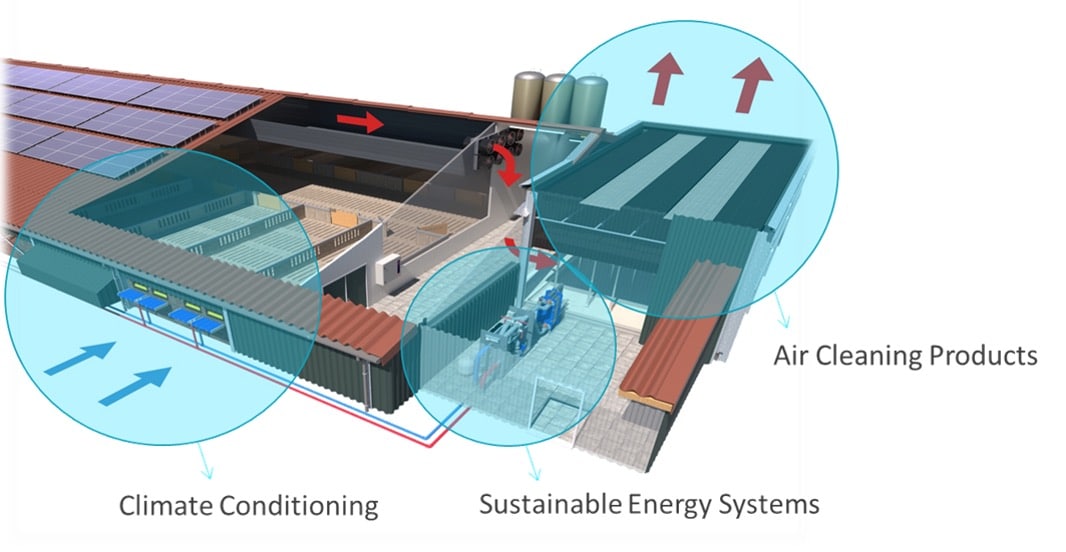

In this third part of my series, I tell you about the possibilities air scrubbers offer in terms of energy recovery, climate optimization and animal performance improvement. Inno+ offers several systems that can turn your air scrubber into a sustainable money earner. By applying these concepts, Belgian livestock farmers can get multiple financial benefits from their investment while reducing their CO2 footprint.

Energy recovery from air scrubbing - a return on investment

By many business owners, an air scrubber is considered an unpleasant expense. However, this need not be the case. 15 years ago, we looked at the possibility of using our system as an energy source. The thinking behind this was that the animals in the barn produce a lot of heat that escapes through the air scrubber’s exhaust. So what if we could capture and reuse this heat? As the warm air flows through the scrubber, the heat is transferred to the wash water circulating in the system. Our idea was to capture and transfer this thermal energy through a heat exchanger, converting the energy from dirty to clean water that can be reused. One such system is the Triple EEE air preheater.

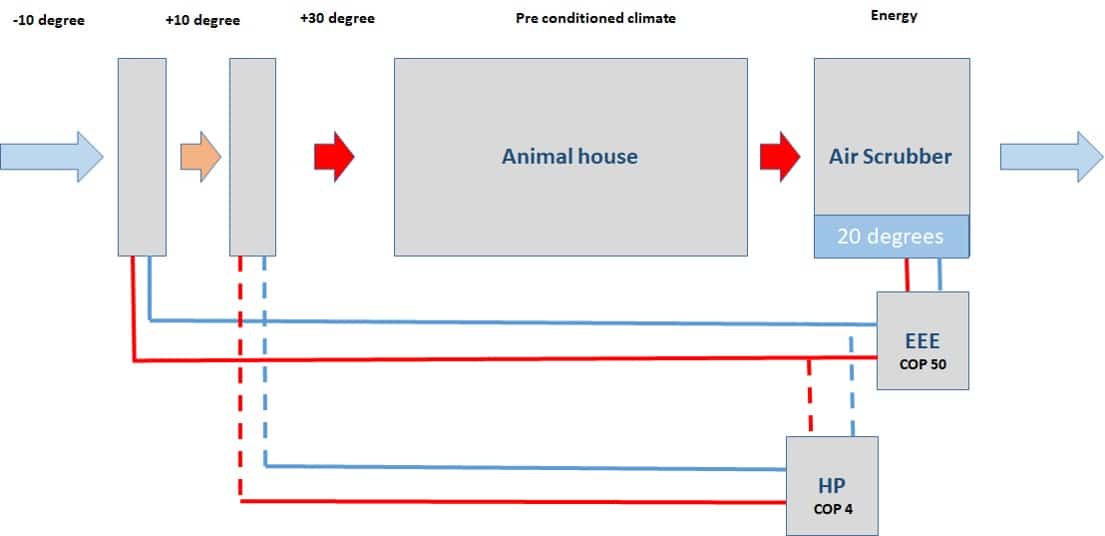

The system allows us to heat the incoming air from -10°C to + 8°C. Which provides significant savings in energy costs during cold periods. Because the air is treated before it enters the animal room, the livestock farmer can also be more flexible with ventilation. The air in the barn can be better conditioned, meaning relative humidity, CO2 and ammonia levels and other pollutants can be reduced. It is widely supported by veterinarians that optimal barn climate has clear benefits:

- Healthier lungs

- Less bacteria

- Better intestinal health

- Less ear and tail biting.

All this leads to better animal performance in terms of growth and feed conversion.

Energy transfer Triple EEE

Energy transfer can be done in one of two steps, depending on the need. First, we transfer thermal energy using a Triple EEE system, where low-latency transfer is high, a COP of 1 in 50. This means that 1kW of electricity is used to transfer 50kW of thermal energy. This energy is then used to pre-treat the incoming air, bridging a difference of up to 20°C.

Gas reduction

The main benefit is that Belgian agricultural entrepreneurs will consume significantly less gas. An installed Triple-EEE system will reduce gas consumption by about 65%. Your heating system then only needs to bring the temperature from +10°C to the desired stable temperature.

Heat pump

As a second step, a heat pump can be added, allowing us to reach higher temperatures of, say, 45°C to bridge the remaining gap to 30°C. Of course, a heat pump with a COP of 1 in 4 is less efficient, but still much more cost-effective than traditional energy sources such as natural gas that have a COP of 1 in 1. By the way, both systems can be used separately or combined.

This diagram shows the energy transfer from the air wash water to the plate exchanger, and from the Triple- EEE plate exchanger to the air inlet. Whereby the air is conditioned from -10 degrees to +10 degrees.

From our many case studies, we see improvement from:

- Gas reductive: 65%

- Feed conversion rate: 4-10%

- Failure rate: 1.5%

- Fattening pig growth: +100g per day

Subsidy in Belgium

As far as we have heard, subsidies in Flanders for sustainable systems like this amount to 40% of the entire investment that must be made to install such a system. This significantly improves the return on investment.

Pig farms - payback period for a typical Belgian pig farmer

The return on investment of an energy recovery system varies with production. However, for a typical pig farm, we see about 3-5 years. This figure is calculated on the energy savings of the system and improved production.

Payback period - piglet house

- Total investment (air scrubber, Triple EEE, heat pump) = €116,535

- Energy cost savings – € 13,528 per year

- Saving of production improvements – € 16,916 per year

- Total savings per year = €30.444 per year

Payback period: 3.83 years

Learn more

- Triple-EEE and payback period

- How a farmer makes money with heat recovery

- ”Ultimate climate” with the Van Asten Group

- Case Study piglet house